Civil Engineering Competition

The time is NOW to build a better future! Gather a team (2-5 members) to compete in CBU’s Civil Engineering Competition September 18, 2023, when up to six teams in each category will test their skills for the judges, CBU’s renowned engineering professors.

Don’t wait! There’s preparation involved, and you’ll want time to learn and build before you come.

Open to all high school sophomores, juniors, and seniors.

Geo Wall Competition

Objective

The objective of this project is to design and build a model wrapped faced mechanically stabilized earth (MSE) retaining wall using kraft paper reinforcement.

Each team is to:

– Design a MSE wall using the least amount of facing and reinforcement material needed to support the retained soil and applied load.

– The applied load will be placed on the top surface of the sand in the “Sandbox”. The load will be increased until the wall catastrophically fails. Catastrophic failure is defined as the face of the wall completely collapsing.

– A team’s final score is given as the magnitude of the supported applied load divided by the weight of the kraft paper used as face material and reinforcement.

The MSE wall will be constructed within an apparatus hereafter referred to as a Sandbox. Each team shall bring their own sandbox to the lab. The Sandbox shall be made up of a bottom and four vertical sides with no top. The front panel will be removable as shown in Figure 1.

Notes:

- Sandbox to be fabricated with plywood, not exceeding ¾” thickness.

- Tie rod must be ¼” diameter threaded steel rod with washers and nuts.

- Handles or knobs may be attached to the outside of the box.

- Interior surface of Sandbox must be natural wood and unmodified.

- Exterior of Sandbox may be painted and decorated with school logos.

- Front panel must be removable.

The removable front panel of the Sandbox will be in place during wall construction and removed after construction to expose the MSE wall. The Sandbox will meet the following requirements:

– Have exterior walls and base constructed of any grade of plywood not to exceed 3/4-inch (19 mm) thick.

– Have planar inside surfaces with the natural plywood finish.

– Have a removable front panel as shown in Figure 1. All panels must be flush with the base of the box and held in place with threaded inserts, screws, hinges or other easily removable fasteners.

– Have a full-sized base such that it extends no more than 3/4 inch (19 mm) beyond the base of the wall once the front panel has been removed.

– Include a steel tie rod designed to keep the two fixed sides of the box parallel after removal of the front (facing) panel.

– Any templates used must be removed after wall construction and before testing.

– All dimensions of the sandbox shall be as shown in Figure 1.

The backfill material will be a well-graded, orange sand with a unit weight of approximately 110 lbs/ft3 and will be provided to the teams on the competition day. The backfill material will be used as-is: dry, no water, no additives, and no chemical stabilizers may be placed in the backfill material.

Material Specifications and Information

The backfill sand, kraft paper, and scissors will be provided by CBU on the day of testing. Facing may be prepared using kraft paper or white poster board material provided. The reinforcement will be prepared from kraft paper only. There are no restrictions on the shape or geometry of reinforcing elements, except that all reinforcement must be cut from kraft paper.

Other construction tools may be used, if desired, but must be provided by the competing team (quantities of these items shall not be restricted):

– Pencils, pens, and markers

– Rulers, straight edges, and levels

– Manually operated cutting instruments (e.g., scissors, utility knifes, razor blades, hole punch)

– Cutting boards or mats

– Design notes, calculations and drawings

– Material handling and compaction tools consisting of any hand operated devices.

– Screwdrivers (battery operated drills or screwdrivers may be used, but only to remove fasteners when removing the facing panels)

– Temporary templates for use in any stage of the competition. These may be made of any material, must not have any moving parts, and must be removed at the end of any stage in which they are used.

Construction and Judging Procedures on Competition Day

Construction and testing of the wall will be done in the following stages:

- Reinforcement Fabrication Stage – Each team will be provided with kraft paper and white poster board. The team must fabricate all their reinforcing elements using authorized construction tools. Twenty (20) minutes will be allotted for this stage. After all reinforcing elements are fabricated, the competition judges will weigh the reinforcing elements.

- Construction Stage – After each team’s reinforcing elements have been fabricated and weighed, the competition judges will instruct the team to start construction. During this stage the team constructs the wrapped MSE wall filling the box with sand and the backfill is level. The facing material must be in direct contact with the inside of the sandbox at all times during this stage. Facing material can be made from the white poster board or kraft paper provided. Temporary templates or guides may be used during this stage so long as they are removed before the end of the stage. The construction stage is complete when the wall is in place, the sand backfill covers the sand fill line and is level, any temporary templates or guides have been removed. Twenty (20) minutes will be allotted for this stage. At the end of the phase, the competition judges will check fill placement to ensure it meets requirements.

- Loading – The loading occurs in two steps: 1) removal of front panel and 2) placement of vertical applied load. During each step, the wall will be checked for catastrophic failure. When directed by competition judges, the team shall remove the front panel of the sandbox. After the front panel is removed, the judges will wait one (1) minute and then check for catastrophic failure. If the wall does not fail catastrophically when the front panel is removed, the team will then proceed to load the apparatus in 10 lb increments until failure occurs.

- Judging- Scoring will be based on a ratio of failure load (lbs) to weight of kraft paper reinforcement and facing material (made from white poster board or kraft paper). The team with the highest load-to-weight ratio wins.

Example

Please note that the references below had slightly different rules than what are given here.

GeoWall Challenge, GeoTech Consultants – YouTube

2019 Geo-Wall competition – YouTube

Summary of Material Specifications

Sand:

- Dry, well-graded, orange sand with a unit weight of approximately 110 lbs/ft3

Sandbox Material:

- Walls and Base: Plywood, not exceeding ¾” thickness.

- Steel Tie Rod: ¼” diameter threaded steel rod with washers and nuts as needed.

- Fasteners: any suitable screws or other wood fasteners. The front panel should be removable.

Reinforcing Material:

- Kraft Paper

Facing Material:

- Kraft Paper or White Poster Board

Water Filtration Competition

Objective

The objective of this competition is to design and build a model filter to minimize the turbidity (cloudiness) of source water and minimize material cost. The source water will be an aqueous solution with an initial turbidity of approximately 100 NTU.

Each team is to:

– Design and build a filter using a 1-liter clear plastic bottle.

– Use any filtration media and chemicals desired to be placed inside the filter.

– Attach one coffee filter at the outflow point.

Teams will build their filters inside a 1-liter clear plastic bottle with the bottom cut off and all labels removed. The filters should be constructed in advance of the competition and brought to the competition ready to test.

Judging Procedures on Competition Day

On the day of the competition, each team will be given turbid water to filter.

- The effluent will be thoroughly stirred prior to filtration to obtain as homogeneous a sample as possible.

- The initial turbidity of the effluent will be determined for each team, before filtration.

- Filters will be placed in a frame apparatus. Approximately 6 oz of water will be collected after filtration.

- The final turbidity of the filtered water will be determined for teach team.

- The team score will be computed as:

S = ΔT – 15L

ΔT = change in turbidity = To – Tf

L = length of filtration material, in inches

K’NEX Bridge Competition

Objective

The objective of this competition is to build a K’NEX bridge to span a chasm and support weight. Figure 1 shows the K’NEX set that will be provided to each team on the competition day. The bridge must span a 10” chasm. The bridge must have a width between 4” and 6” and a height between 6” and 10”. Bridges should be no less than 12 inches long and no more than 14 inches long. All dimensions are measured from outer edge to outer edge of members. If any of these dimensions are violated, the team will be disqualified.

Judging Procedures on Competition Day

On the day of the competition, each team will be provided one K’NEX kit, as shown in Figure 1.

- Each team will be given 30 minutes to build their bridge. At the 30-minute mark, the bridges will be weighed.

- Loading – A hanger will be hung from the bottom deck of the bridge within a notch that is at least 1 inch long in the middle of the deck, shown in Figure 2. Plates will be hung from the hanger and the load will be increased until failure.

- Judging – Scoring will be based on a ratio of failure load (lbs) to weight of the K’NEX bridge. The team with the highest load-to-weight ratio wins.

Applied Mathematics Competition

Maximum Team Size: 3 students

Target Participants: High school students who are currently enrolled in Algebra 2 or higher.

Calculator Specification: Each student may use one calculator that comes from the below list. No other calculators (or phones) are allowed during this competition. ONLY calculators on the list below are allowed.

Calculator Specifications

Casio Models: All fx-115 models. Any Casio calculator must contain fx-115 in its model name.

- fx-115 MS

- fx-115 MS Plus

- fx-115 MS SR

- fx-115 ES

- fx-115 ES Plus

Texas Instruments Models: All TI-30X and TI-36X models. Any Texas Instruments calculator must contain either TI-30X or TI-36X in its model name.

- TI-30Xa

- TI-30Xa SOLAR

- TI-30Xa SE

- TI-30XS Multiview

- TI-30X IIB

- TI-30X IIS

- TI-36X II

- TI-36X SOLAR

- TI-36X Pro

Objective

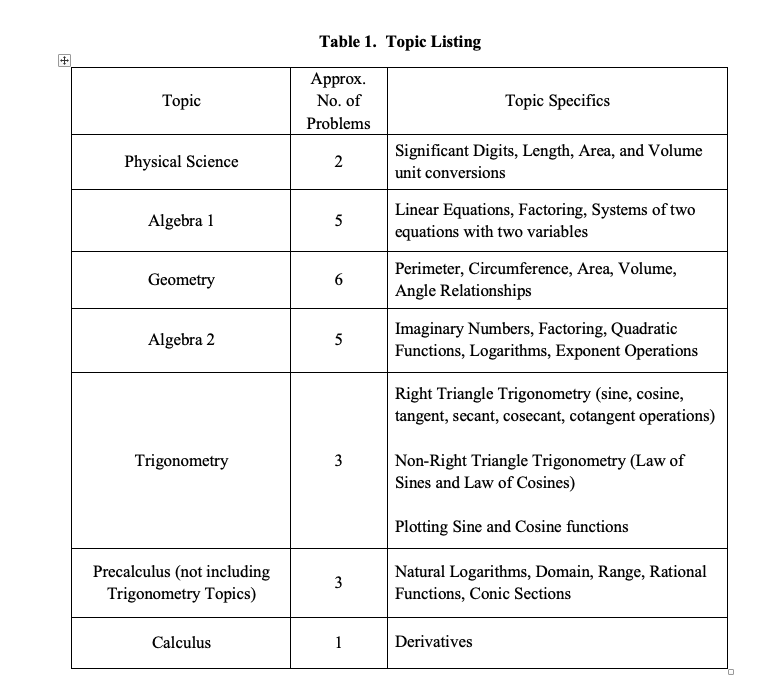

The objective of this competition is for students to work in teams (up to 3 members) to solve a set of applied mathematics problems. The maximum time allotted is 1 hour and there are 25 problems. Topics are selected from Physical Science, Algebra 1, Geometry, Algebra 2, Trigonometry, Precalculus, and Calculus with the distribution summarized in Table 1. Approximately one third of these problems will be word problems. All problems are short-answer and students must show their work to receive credit. Partial credit may be awarded.

Questions? Contact Us.

If you have questions on any of the competitions please reach out to Dr. Andrew Assadollahi.